- Brick Making Machinery[343]

- Marble[2]

- Curb & Paving Stone Forming Machinery[7]

- Tile Making Machinery[55]

- Other Construction Material Making Machinery[12]

- Pipe Making Machinery[9]

- Lift Tables[1]

- Moulds[1]

- Other Machinery[2]

- Cement Making Machinery[2]

- Silos[4]

- Mixing Equipment[6]

- Concrete Mixers[6]

- Crusher[1]

- Road Roller[5]

- Contact Person : Mr. ji Andrew

- Company Name : Shandong Hongfa Scientific Industrial & Trading Co., Ltd.

- Tel : 86-539-3558050

- Fax : 86-0539-3552198

- Address : Shandong,linyi,Dazhuang Economic & Developing Zone, Yinan County, Shandong

- Country/Region : China

- Zip : 276305

QT10-15 automatic brick making machine

Detailed Product Description

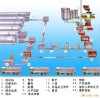

QT10-15 automatic brick making machine

1.Particular storage and discerption material system insure the feeding accuracy and avoiding the effect of exterior material. So the products made by this automatic brick making machine have high density.

2.Adopting synchronization vibration insures the products making average. The frequency can change according to different technics. Low frequency in feeding material, high frequency vibration makes the different material to have a optimal vibration way.

3.The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis.

Productvity of automatic brick making machine

Size | Quantity | Cycle moulding | Per hour | Per day | |

Hollow brick | 400*200*200 | 10 | 20-25s | 1800pcs | 18000pcs |

Porous brick | 240*115*90 | 28 | 15-20s | 6720pcs | 67200pcs |

Standard brick | 240*115*53 | 52 | 15-17s | 12480pcs | 124800pcs |

Main Production Specification of automatic brick making machine

Main Technical Specifications | |

Overall Dimension | 9350*2320*29500mm |

Rated Pressure | 21MPa |

Main Vibration Form | Platform vibration |

Cycle Time | 15-25 seconds |

Vibrating Frequency | 2800 -4500 rolls/minute |

Motors Power | 44.58KW |

Pallet Size | 1100*900mm |

Raw Materials | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

Applied Products | concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

Applied Fields | widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |